Unsanded Multipurpose Grout

Product Description

Unsanded cement-based grout with high performance polymers that oers a smooth and shiny nish on oors and walls for joints up to 1/8’’ (3mm). It can be used on installations of porcelain, ceramics, glass and mosaic tiles. It is mold and high trac resistant. Due high resistance and good quality, it is recommended to be applied on interior and exterior installations. Meets ANSI A118.6 standards.

Suitable Substrates

- Ceramic Tiles

- Quarry tiles

- Porcelain

- Glazed tiles

- Mosaics

- Granite

- Dimension Stones

Properties

- Excellent workability and creamy appearance

- Proper hardening without cracks

- Anti-mold formula

- Water resistant

- Stable color with lighting

- Acid resistant

- Easy lling joints

- Good mechanical and abrasive resistance

Precautions and Warnings

Precautions for safe handling should be taken as required by OSHA’ Respirator Standard (29 CFR 1910.134) and ANSI’Standard for Respiratory Protection (Z88.2).Proper ventilation is required. A dust mask or filter mask is recommended in poorly ventilated areas with a NIOSH approved respirator. It is a recommended to wear eye protection goggles as well as the protection of gloves of adequate size to protect the skin from splashes. Avoid contact with eyes, skin or clothing. This product containtssilica and cement. Direct and prolonged contact may cause silicosis. According to animal studies, it may be carcinogenic. This mortar contains Portland cement and may have detectable amounts of chemicals that could cause cancer, birth defects, or other reproductive harm.Cement, slurry, or foodstuffs. Remove contaminated clothing and wash hands before handling food or contact with eyes and skin. If eye contact occurs, flush eyes with plenty of water several times and consult a physician if necessary. Do not allow this material to enter drains or sewers. Dispose of the material in accordance with the regulations. This substance is harmful if swallowed. If ingested accidentally rinse mouth, DO NOT CAUSE VOMITING. KEEP OUT OF REACH OF CHILDREN

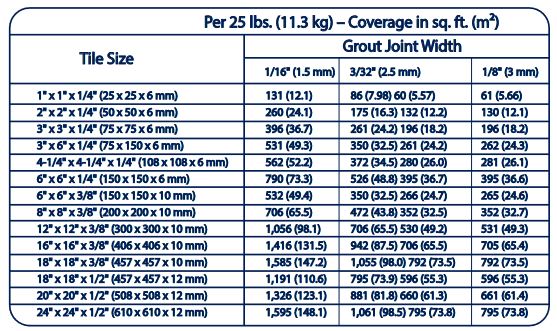

Coverage:

Directions For Use:

Directions For Use:

For every 50 pound bag. (23kg) add 1.5 gallons (5.7 liters) of water to room temperature. A homogenous and plastic mass should be obtained. Let stand for 10 minutes and mix again before use. The mixture should have sufficient consistency to be applied with a spatula. If using a mixer, mix at low speeds, 150 rpm. Extend the mortar manually over the surface with the smooth side of the spatula,then use the serrated side to give the Atria Extra-Bond a thickness of 0.19 inches or 5 milimeters. For best results in small areas, spread the mixture and immediately place pressure on the surface and level. Immediately remove excess mortar that may have leaked through the joints. For surface with verse protuberances, it may be necessary to apply the mixture on the back of the cover.

Drying / Curing Time

The minimum curse is reached after 24 hours, depending on the temperature and humidity. After placing the Atria ExtraBond you must wait 24 hours to seal the joints.

Storage

It can be stored, free of moisture, in its original packaging for up to 12 months. Do not allow water to come into contact with the product until it is in use.

Cleaning

Only water is needed to remove excess uncured mortar and cleaning tools.

Warranty

Atria Industries Corp. Warrants the good performance of this product for the purpose it was created only within 90 days from the date of manufacture. Atria Industries Corp.only responsibility will be to replace the product considered to be defective by Atria Industries Corp. after a written claim is received along with samples of the material. Atria Industries Corp. does not provide any other kind of warranty including any warranty of merchantability or fitness express or implied. The user is the only responsible of determining the proper and suitable use of the product. Under no circumstances Atria Industries Corp. will be responsible for damages of any kind or nature. Atria industries Corp. only responsibility will be to replace the product considered to be defective by Atria Industries Corp.